Stage 1 - Quotation

· 1. Customer provide 2D/3D file or samples with mould spec for RFQ

· 2. We can provide professional quotation within three days

· 3. We will start mold after receive customer order

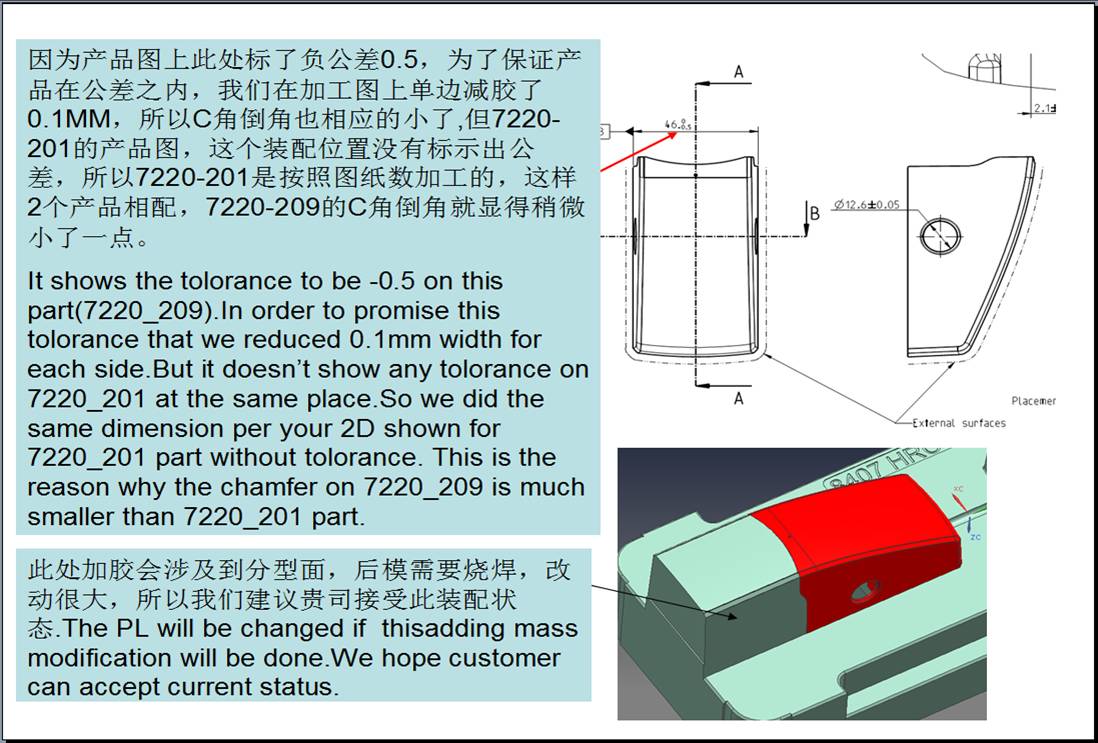

· 1. Provide Design for Manufacturing (DFM) report including part optimization analysis,mould feasibility , mold-flow ,

material analysis,mould process analysis and mould injection analysis.

· 2.Customer confirm all analysis report

· 3. Submit mold design drawing

· 4. Customer confirm design drawing

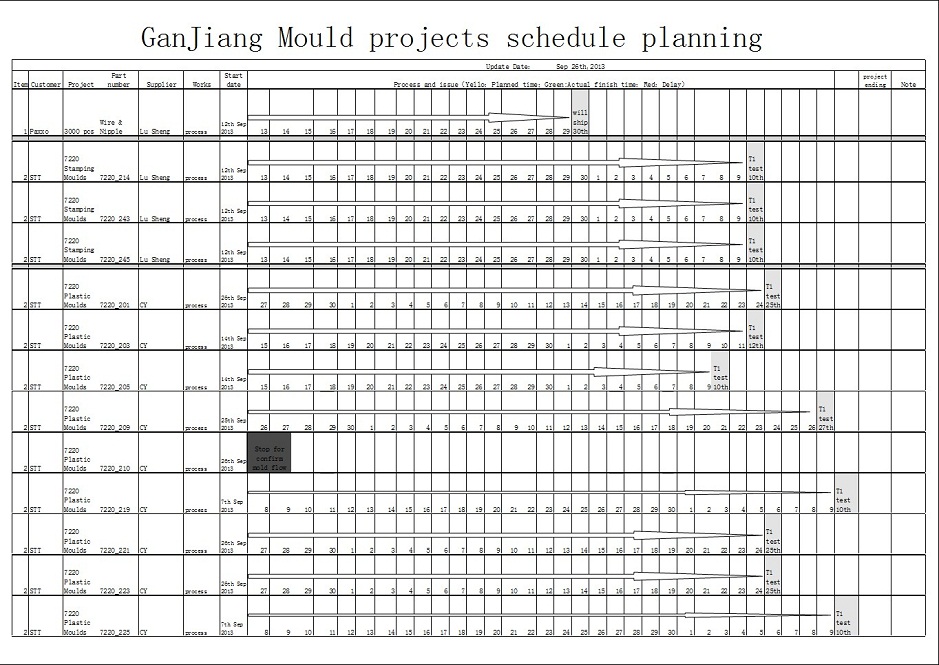

· 5. Publish mould information table and process schedule planning

Stage 3 – Tooling

· 1. Preside over process technology study meeting

· 2. Order steel and plastic material.

· 3. Process mould and ensure ongoing work are implemented basing on customer's specifications

· 4. Provide with latest mould information table, process schedule and machining photos weekly

Stage 4 - Mould Trials

· 1. We will arrange free three times mould trials on customer's specifications

· 2. Mould trials discussion meeting after got samples

· 4.Mould correction reports (sample defects review and recommend actions)

Stage 5 - Mould Delivery

· 1.OQC inspect mould,including, rust protection,waterway,packing,and files

· 2. Provide mould, electrode,drawing, injection parameter,wooden box and arrange to ship.

· 3.We will provide after-sales service after ship

Stage 6 – Mould injection(mould injection in GanJiang)

· 1.We will arrange mould injection on customer’s specifications,and our IPQC will inspect them

during the whole injection,and our OQC will double inspect before ship.

· 2. Provide OQC inspection report, CPK document